for quite a few years, companies that sell and manufacture copper based CAT ethernet cables have been demonising CCA (Copper clad Aluminium) cables, with some even stating that standards such as cat5e define having pure copper at as part of the spec.

What is a RJ45 ethernet cable?

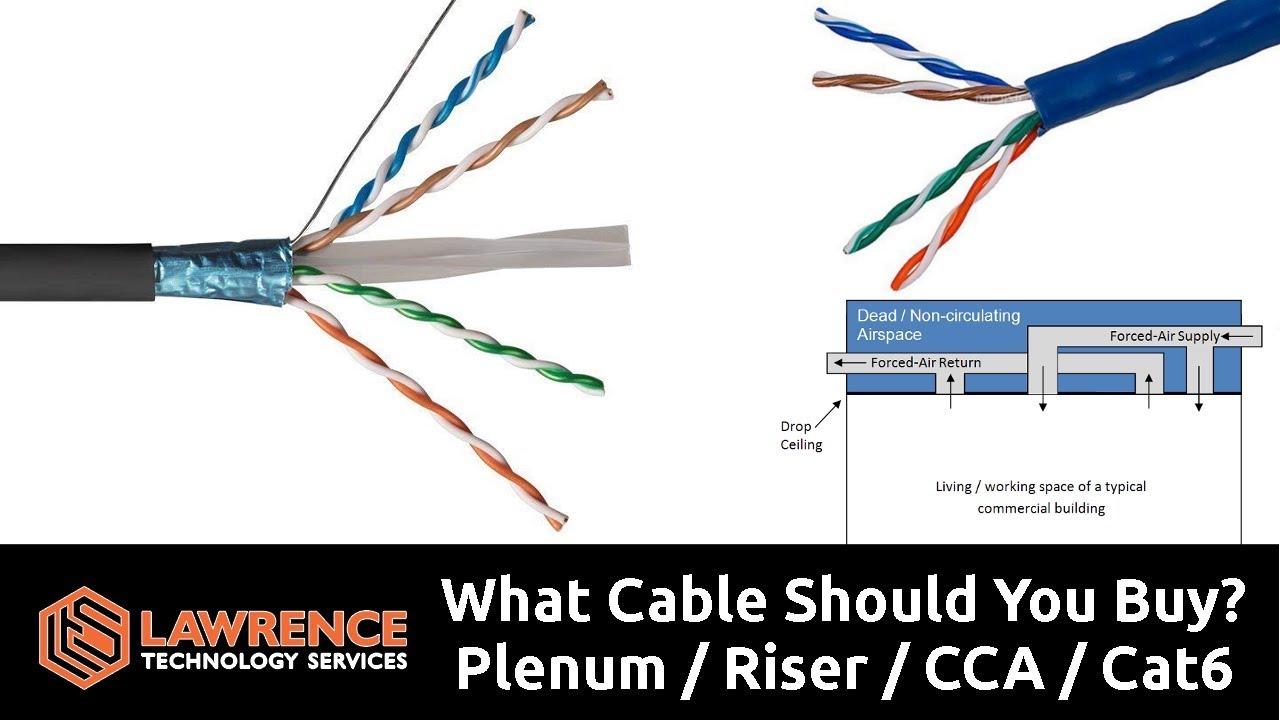

So how to identify if its CCA or full copper? Shine a light or look at the 4 pairs of conductor of the cable from the flat exposed surface with a lot of light. Move it and see how it shines and its colour. Metallic grey is aluminium (CCA) while the brown/orange colour is copper. CCA has a little bit of copper so if you look at it right from above or from different angles you would notice the metallic grey and brown/orange colour appearing. If you have good eyes and a good source of light you’ll be able to tell the difference by looking at the end of the cable head for ready made cables. If you buy a spool, strip a bit and check, then measure the width of the conductor to confirm. if it says 23 awg of c onductor it better have that much, although for this i highly suggest a set of digital calipers.

First it is important to understand how the ethernet cables are defined and used. They arent only used for computer networks but a single cat5e cable can be split to carry 4 phone circuits as well though cat3 allows up to 3 pairs (6 cables inside) for other reasons with only 2 pairs needed for a 100Mb/s network. They can be used for many other applications such as passive connections with audio or even HDMI to carry video and audio signals over long distances at a much lower cost, and can also be used to carry power as well usually in line with POE (Power over Ethernet) which some devices use to receive power and also for networking. Ethernet cables have a lot of uses other than just computer networks and have their limitations as well.

To understand more about the situation, copper itself is getting harder to find and mine new. Average mining yields for copper are around 0.01% making the production of new copper scarce which affects the prices of your pure copper cables. Copper is great for passing electricity but in signaling applications, it does not matter how conductive an element is, i mean we pass data through air which we call wifi. My most hated ISPs (cable) brag about being able to pass gigabits of data through a single steel cable. In motherboards, copper is only used for power while a combination of other metals form the substrate of those super tiny lanes that wont even hold an amp to pass data at super high rates not to mention silicon which is only a semi conductor passing data in the order of Terabytes a second within the CPUs themselves between the cache and core. You dont need a good conductor to pass data at high speeds but you do need a good conductor to pass high amount of current although you can always up the voltage to reduce your current capacity needs. This make companies that only sell pure copper ethernet cables to scream as more people buy CCA due to lower pricing. Next time you want to throw something away, if its metal make sure to recycle it or you may find metallic products to continue to inflate in price.

Basic Signaling

The ability of a material to pass data is all about the modulation and frequency used. Frequency does affects range (due to the inverse square law) but for something like the range in a motherboard, where you only have centimeters until the next chip, you can use very high frequencies with the same modulation and enjoy a lot more bandwidth. The same goes for ethernet as the higher the frequency of the signal, the more bandwidth you get. Newer technology and better modulation also significantly increase bandwidth and cable tolerance that going from 100Mhz (gigabit ethernet) to 250Mhz (10Gb/s internet) yields a 10x increase in speed over only a 2.5x increase in frequency.

In summary, how conductive or low resistance a material is doesnt affect the ability of material to pass data as even that can be done mechanically with stones if you desire as done in ancient times. Lower quality cables of either will always have problems in speed and errors irregardless of CCA or copper.

Considering the material aspects, lower quality CCA cables tend to be stiffer. The ability for the cable to sharply bend is important when you package or carry the cable with you around. You will often find big brands shipping their products with CCA cables. I have gotten so many cables for free through devices and such and found that they tend to be CCA (after replacing their heads). Copper CAT cables tend to be softer and easier to bend compared to CCA but that does not always apply since even for the same time of cable as there are many ways you can treat the metal and combine them (in the case of CCA) including how much copper or aluminium you use.

From my experience in cables, stiff CCA cables are terrible for short runs and tend to lose connection after being sharply folded requiring heads to be replaced or maybe even recrimping if lucky. Although ethernet heads can be gotten cheaply the costs do add up, so you wont save money if you expect to be carrying cables or using them as jumpers. Some CCA cables are very flexible that come free or that you can buy, only replacing the heads after wear and the clip breaking. So the fact that CCA cables tend to have more issues in this regard to physical may not be true from my experience in comparison to copper as the way the cable is made, the metal composition and how it goes together does affect final product. You can find CCA cables with better insulation than full copper too as insulation is an important aspect of the cable. The flammability of the cable at high temperatures is important and in some places aluminium may be banned in buildings because when aluminium burns its toxic capable of killing the occupants..

Practical

Using the cables practically, many cables that are inferior use CCA because it is much cheaper in the first place and this is why copper cable manufacturers demonise CCA because the low quality manufacturers get away with selling cheap cable out of spec. These cables may seem like cat6 when they can only obtain a 100Mb/s link between intolerant NICs despite having all 4 pairs properly set up. Some devices like my business/enterprise grade switches can sync at 1Gb/s using these inferior cables between themselves without errors (switch will auto drop speeds if errors are detected because of cables).

However despite this inferiority complex, the one advantage that CCA cables have over full copper is that they are only a little less susceptible to interference thanks to the increased resistance/lower conductivity however the more significant trade off is that CCA cables suck at POE, so do not ever consider them if you plan on using POE which many enterprise grade wifi APs have, and many security cams and sensors for example. Even some smart home devices can be powered with POE.

When terminating the cables, the good cables are easier to terminate than low quality irregardless if full copper or CCA. Some may say that cat5e is easier than cat6 but that extra step of cutting the inside structure is very trivial. Trying to get the 4 pairs into the head properly and making sure it goes in in the right order without swapping around is the hard part. With full copper or good CCA, this is achievable in 1-2 tries as the copper either stays the way you bent it or for CCA stays the way you bent it and harder to get out of line when inserting. So the argument that CCA cables are harder to terminate is simply not true. However the thicker conductor of using cat6 instead of cat5e makes cat6 better for integrating into buildings for sockets since they are harder to move about.

Structure of a CCA cable – simple diagram. Copper coated over aluminium (amounts of both vary by manufacturer, etc, so many variations).]

So when you plan to wire up a place for ethernet cabling, the first is to check your needs and budget, though with some things to never compromise on. Firstly, any cable that goes into walls, ceilings and so on should always be full copper, reason being the re-usability and in some cases the law. Due to POE and the universability of the rj45 and CAT standard, so many different applications use this cable, from power to different types of data, even passive media conversion such as HDMI, not to mention a single cat5e and better cable supporting 4 phone lines for example saving you 3-4x in cat3 cable lengths and some in costs. So heres the rundown of how to decide. Most ethernet cables are UTP (Unshielded Twisted pair) and STP (shielded twisted pair). If the cable is not twisted, dont bother as twisting reduces interference by making it consistent over all conductors making it easy to detect and compensate for.

1) If its going to be integrated into the building, the only option is full copper

2) pick the cat standard based on max speeds. Cat5e will be rated for 2.5Gb/s up to 100meters, cat6 5Gb/s up to 100 meters, 10gb/s at 50 meters.

3) where and how cable is used

Stiff CCA:

– stationary runs that are visible (not part of buildings) and attached to things (cant be moved)

– when your budget is low

– the cable will not be moved, touched or folded

CCA

– when your budget is low

– cable might be moved, lost or damaged easily requiring replacements often

Full copper

– POE applications

– cable being integrated into building out of sight

– when your budget isnt too low

– everywhere not suitable for CCA

Shielded

– when you have to run over high sources of interference like high voltage AC lines, scientific or medical machinary and so on that emit high levels of emf.

Armoured

– when you have to run cable outdoors or through nasty environments, however you can also run your common UTP through pipes as well.

FOR THE LAST TIME DO NOT EVER CONSIDER CCA FOR ANY POWER BASED APPLICATIONS OR POE SO STOP ASKING. PONY UP AND USE FULL COPPER.

Conclusion

The truth of the matter that sparked the bashing of CCA is that full copper cables are more expensive, and many low quality cables use CCA, however many decent cable manufacturers that make full copper cables also make CCA cables. quite often will you see a brand selling both spools of copper and CCA cables. Low quality cables however will tend to suffer from issues as most consumer devices have NICs that are less tolerant to this. Manufacturers of full copper cable also feel threatened by the super low pricing of low quality CCA cables, however i have news for you. It is also cheaper to buy your own copper cable and to crimp it yourself than it is to buy a ready made low quality CCA cable if you can use all the meters of cable that come in the box. I suggest full copper cable manufacturers to try and compete, and instead of demonising and pushing people towards CCA to educate your users properly, offer both options and help them to make the right choice based on their needs.

So if you can, use full copper cables, otherwise check if your applied use of CCA will fit into one of the categories above. I have spent a couple of years between ready made CCA cables, making your own CCA or full copper cables, and even using cables that come with devices. Do not let the price be the factor but rather what your needs are. Quite a lot of low quality cables are out there that sell for the same price as the good ones that will cause you too many headaches when you finally realise your devices arent making full use of the said specs of the cable (i.e. getting 100Mb/s on any cat5e or better cable). The CCA cable i bought for instance thats supposed to be good (and is cat6) turns out to be the biggest pain nthat tends to pull out its own internal cables during short runs or tight folds that cause loss of connectivity. If you really want to save money, get a spool, ethernet heads and the tools (this is very cheap) and start running your own cable and save loads. It is very easy to make your own ethernet cable.

Sorry for the terrible images below, i didnt have my DSLR with me. The cables are much much easier to identify with the eye and much easier the higher up the standard you go as the larger conductor makes the metal more apparent.

Dull metallic grey if you have a good sight to see. At some angles if you shine a light the copper is visible so make sure to move it around with good light to identify it.

Shiny metallic grey visible from the exposed inner wires. Shining a light does help

Hard to make out on camera but if you zoom in you’ll see some exposed copper on the head. Not so easy to make out on cat5e of an already terminated cable

If you zoom in, you’ll notice that all the reflected light on the shiny exposed inner metal wires to be copper rather than metallic grey.

So yes CCA has been overly demonised because many low quality manufacturers produce CCA cables, however with the low yields of copper mining, there isnt much choice in the higher pricing so pick based on what matches your needs best. If you buy a cable spool, create a patch of short cable and give it a test making sure it is capable of syncing at the speeds of that standard. The better conductivity of copper doesnt magically make it better for signaling as the traces in your board or CPU dont even use it for such high bandwidth and high speeds/frequencies, but it does matter for transferring those amps your POE WIFI AP may need or that POE CCTV.

I would like to thank the respective sites for their images in helping readers identify what the cables are and how to differentiate them.